Auto Parts Semi-Metallic Brake Pad for Jpanese Car D537/Wva23652

Shandong Jinli New Material Tech Co., Ltd.- After-sales Service:50000kms

- Warranty:50000kms

- Type:Brake Pads

- Material:Non-Asbestos

- Position:Rear

- Certification:ISO,TS16949, IATF-16949, ISO9001, AMECA

Base Info

- Model NO.:D537-7418,43022-SM4-G00, 43022-SM4-G00

- Classification:Disc

- Main Market:North America

- Fricton Material:Ceramic,Semi-Metallic

- Transport Package:Shrink Wrap-Box-Carton-Pallet

- Specification:88.7*47.5*14.6

- Trademark:Negotiable

- Origin:China

- HS Code:870831000

- Production Capacity:200000sets

Description

43022-SM4-G00

CL

ILX

Integra

RSX

TL

TSX

Honda Car

Accord

Civic

CR-Z

Prelude

S2000

Suzuki Car

Kizashi

SX4

2013-2019

1998

2000-2001

2002-2006

1997-1998

2004-2008

1991-2007

2002-2015

2011-2015

1992-2001

2010-2013

2007-2013

Our advantage:

1. Copper Free Ceramic

Green formula

Asbestos free

No heavy metal

Protect environment

Passed American NSF ,AMECA

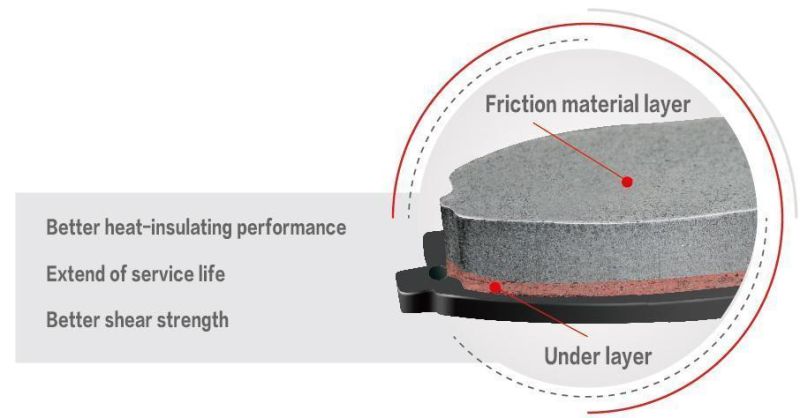

2.Under layer used same as OEM product

3. High performance,shortor brake distance,saferStill got high

braking power

above 600 °C

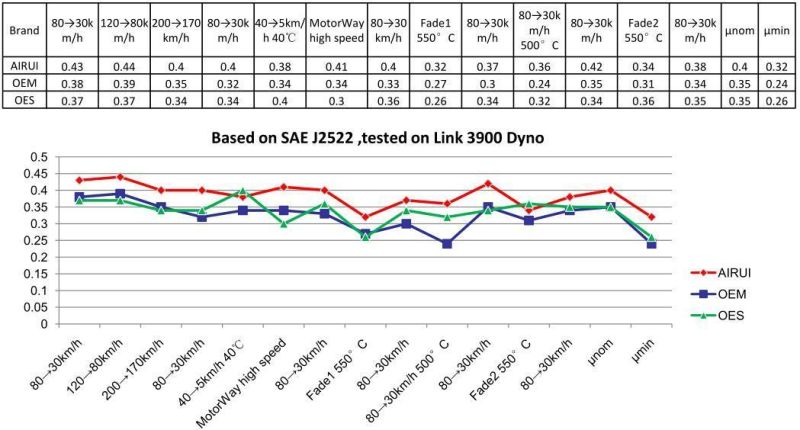

JINLI Formula Compare with OEM & OES brake pads

JINLI Formula Compare with OEM & OES brake pads

Our factory advantage:

1. Improved positive mold, make the thickness, flatness ,hardness and density

more accurate. Make brake pads performance more stable.

2. Can develop new mold in house, more than 30 part number a month.

3. Have an experienced team to develop formula, have 2 Dyno in house to test formula.

LINK Dyno 3900 can make more accurate testing results.

4. We can develop different type formula in house, include Ceramic, Copper free Ceramic, low metal, semi metal ,high carbon etc..

5. More than 2000 part number for brake pads

6. Quality control

Check incoming material every batch

Check shear and density etc. for brake pads every batch

Auto weighing and mixing system ,controlled by computer

Bar code scanning system to avoid mistake

7S control every process