Air Ride Suspension Bag Industral Machine Standard Rubber Air Spring System

Guangzhou Guomat Auto Parts Co., Ltd.- Warranty:12 Months

- Part:Air Spring

- Position:Front,Rear

- Type:Gas-Filled

- Spring Type:Air Spring

- Spring Material:Rubber

Base Info

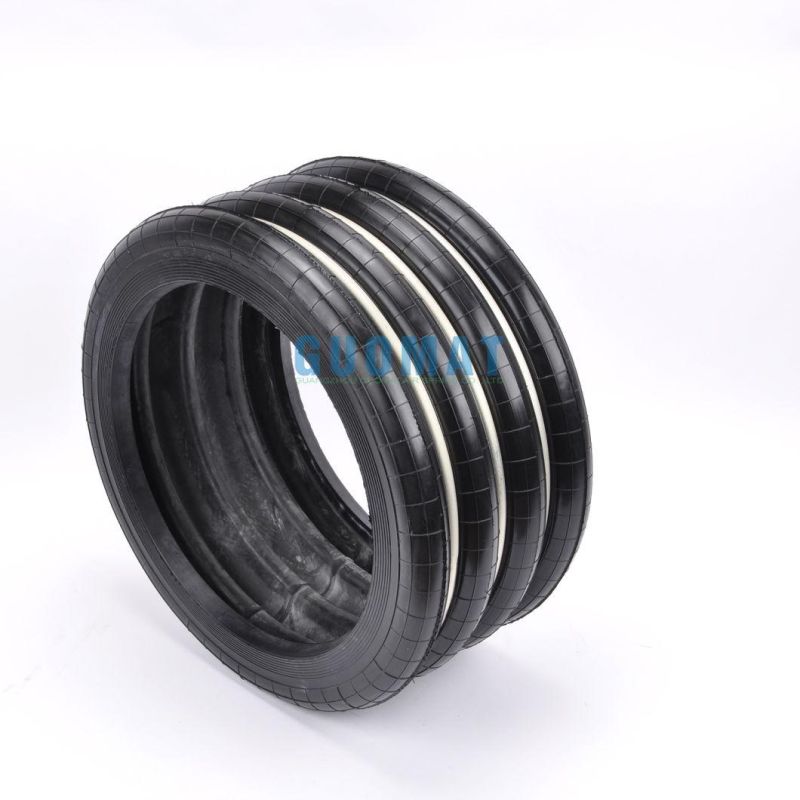

- Model NO.:F-450-4

- Structure:Quintuple Convoluted

- Brand:Guomat or Neutral

- Damping Force Direction:Bidirectional

- Product Size:Standard

- Application:Industrial Punching Machine

- Bellow Quantity:Three

- Function:Reduce Shock

- Transport Package:Cartons

- Specification:33*33*22(cm)

- Trademark:GUOMAT

- Origin:Guangzhou

- HS Code:8708809000

- Production Capacity:5000PCS,Month

Description

Min Height

(mm)

Effective Area

(cm2)

Load

(KN)

Dynamic Spring Constant

(n/mm)

Natural Vibration Frequency

(Hz)

Maximum Internal Pressure

(MPa)

Do you know what role air springs play in industry?

Air springs are used in a variety of mechanical devices to dampen and absorb vibration, control motion or increase pressure. Compared with air cylinders or other elastic elements with the same function, the air spring has a simple structure, reliable operation, no complicated parameter calculation and structural design, no seal leakage, convenient use and maintenance, and long service life.

During the stamping process such as stamping, the car cover, door, etc., should use the necessary buffer devices. The buffer must withstand large periodic shock loads during handling. Its performance directly affects the machining accuracy of the product. Using air springs as buffers can reduce machining costs and ensure machining accuracy. In material conveying, the silo is driven by a vibrator to make the material evenly mixed or flow into the silo. Vibration can cause fatigue and even damage the bin supports, so vibration isolation devices must be used.

More flexibility is provided if air springs are used. Adjusting the amount of spring inflation can meet different working load and height requirements without affecting the vibration isolation effect.

GUOMAT Also Productes other related Air Spring

Product Image