Mesh Hooked Spine Backplate Truck Brake Pad 29125

Qingdao Pujie Industry Co., Ltd.- Warranty:60, 000-80, 000 Kilometers

- Type:Brake Pads

- Material:Semi-Metal

- Position:Front

- Certification:ISO,TS16949, ISO9001, DOT, ECE

- Classification:Disc

Base Info

- Model NO.:29125

- Drum Brakes Classification:Brake Pad

- Main Market:Northern Europe

- O.E. No.:29125

- Width:249.2 mm

- Height:111 mm

- Thickness:29mm

- MOQ:200 Sets

- Transport Package:Neutral Packing or at Buyer′s Request

- Specification:CE, SGS, ISO, TS16949

- Trademark:Pujie

- Origin:Qingdao, China

- HS Code:87083095

- Production Capacity:300, 000 PCS,Year

Description

Basic Info.

Model NO. 29125 Drum Brakes Classification Brake Pad Main Market Northern Europe O.E. No. 29125 Width 249.2 mm Height 111 mm Thickness 29mm MOQ 200 Sets Transport Package Neutral Packing or at Buyer′s Request Specification CE, SGS, ISO, TS16949 Trademark Pujie Origin Qingdao, China HS Code 87083095 Production Capacity 300, 000 PCS/YearProduct Description

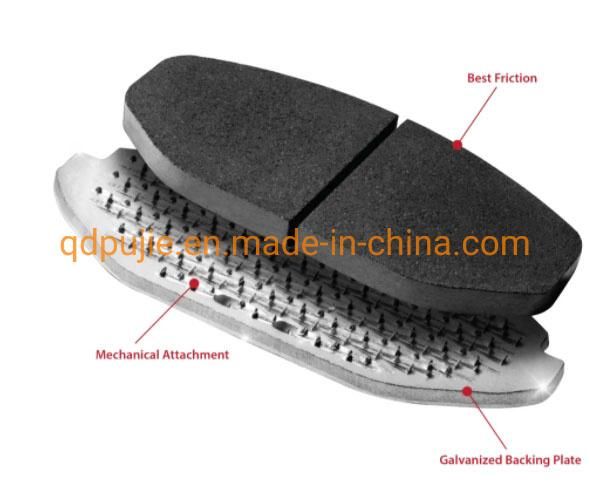

1. Features :Benefits of Galvanized Steel

- Corrosion resistance superior to powder coating

- Longer product life: Galvanized steel will outlast the friction material

- Fit and function is improved, reduced returns, noise benefits

- Premium product that matches OE

- Visually appealing

- Ensures optimal performance over time

- No possibility of damage

- Perfect for harsh environments like braking

- The zinc coating forms its own oxide coating over time, further protecting steel from corrosion

- Environmentally friendly, 100% recyclable

2.The Role of Backing Plates in Brake Pads

our car's braking system is composed of various mechanical parts that work in tandem to bring your vehicle to a halt. Ultimately, friction material presses against the rotor of your wheel and your car stops. This friction material is attached to a steel part known as a backing plate. Friction material and steel backing plates are attached in one of two ways, either through adhesives which can breakdown or through mechanical attachment such as PUJIE™.

The harsh braking climate can lead to brake pad failure as a result of separation between friction material and the backing plate. This can result from adhesive breakdown which leads to a complete separation between friction material and braking plate. Inferior steel can also lead to brake pad failure, highlighting the importance of using steel which is either pickled and oiled or galvanized.

Equally important to attachment, backing plates should fit and function within the brake caliper. PUJIE backing plates meet this requirement.

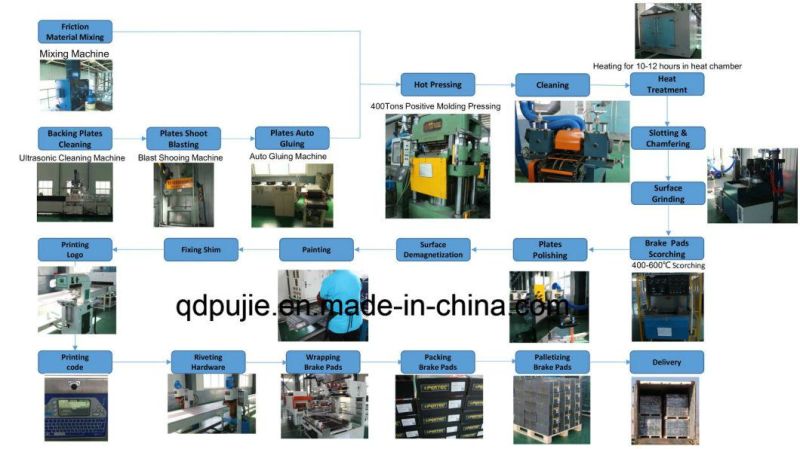

3. Factory show :